612 A ShenHui Building XIXIAN Road Baoan District Shenzhen 518000 Guangdong China

|

What is custom industrial valve

Custom industrial valves are valves that are specially designed and manufactured according to specific customer needs and application scenarios. Unlike standardised valves, custom industrial valves can be adapted to meet specific customer requirements, including material selection, size, pressure rating, temperature range and special features.

WKT custom valves are widely used in a variety of industries such as petrochemical, food and beverage, biopharmaceutical, semiconductor manufacturing and industrial water treatment. The main advantage of custom industrial valves is that they are better able to meet the needs of a particular process and improve productivity and safety.

|

Why choose custom valves?

1. Individual solutions: custom valves can be designed and manufactured for specific custom valve applications, which means they are better able to meet specific needs rather than using generic valve sizes.

2. Return on investment: customised automation valves not only improve reliability, but may also reduce long-term costs. Valves designed using specialist knowledge and experience can provide more optimised performance.

3. Time and resource savings: Automated valves can result in significant savings in time, effort and resources, which is important in all industries.

|

Custom valves vs Finished valves

Custom valves

Design Flexibility: Designed for specific applications and needs, perfectly suited to specific operating conditions and environments.

Performance Matching: Can be optimised to improve efficiency and reliability.

Material Selection: The most suitable material can be selected to improve the service life of the valve.

Dimensions and specifications: The size and shape can be customised to suit special occasions.

Cost: Higher

Delivery lead time: Longer, time for production preparation.

Scope of application: Suitable for special or extreme working conditions

Finished valves

Design Flexibility: Standardised design for a wide range of general purpose applications.

Performance Matching: Provides standard performance that may not be perfectly suited to a specific application.

Material Selection: Uses standard materials, suitable for most general purpose environments.

Dimensions and specifications: Standard dimensions are available to accommodate conventional piping systems.

Cost: Lower

Delivery lead time: Shorter, usually available from stock.

Scope of application: standardised industrial applications, high versatility.

| Custom valve process

Design and Engineering

Material Procurement

Manufacturing and Processing

Assembly and Testing

Surface Treatment

Final Inspection and Packaging

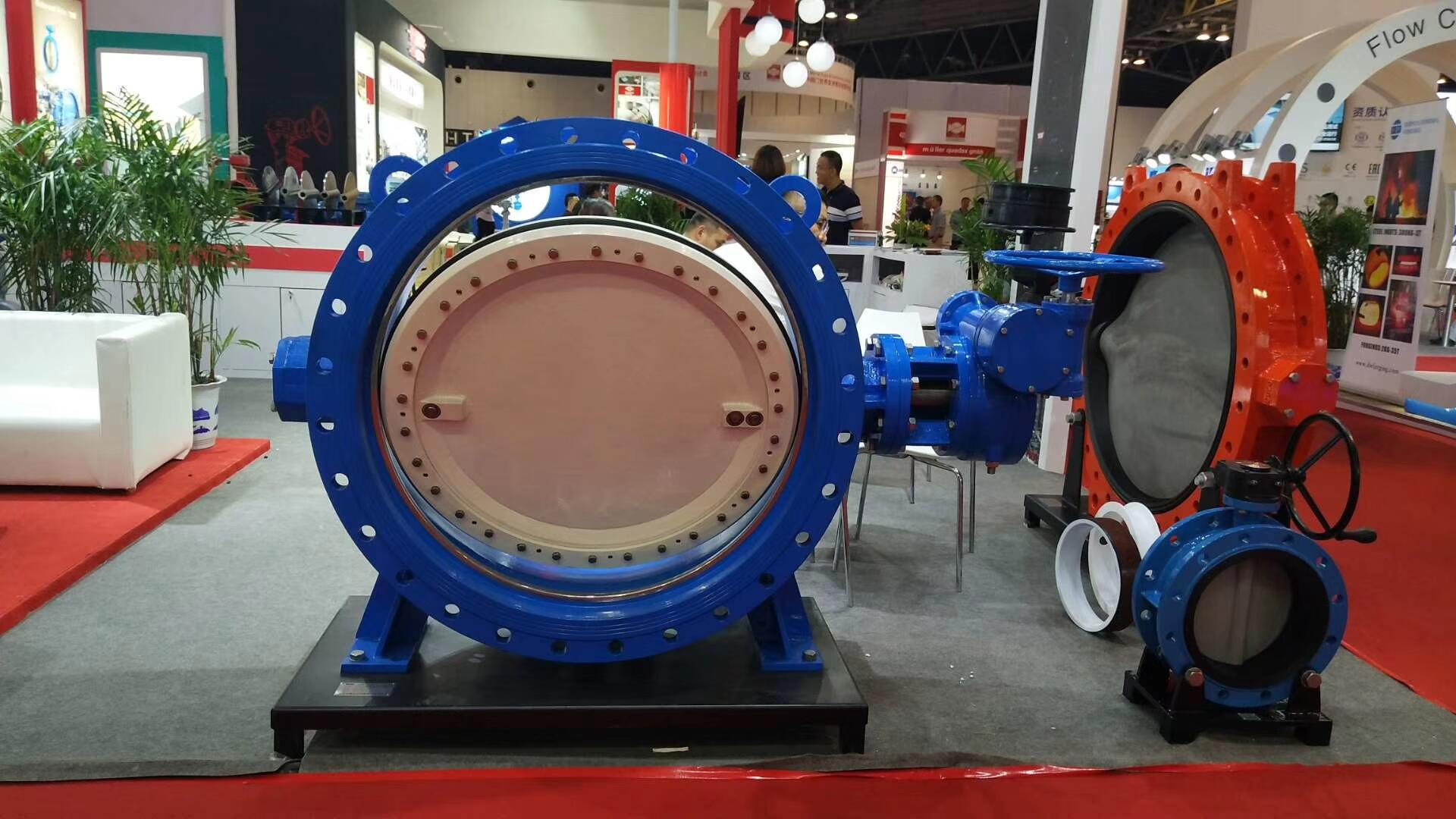

| WKT Custom Valve Factory Site

|

Related articles

| Eight Necessary Technical Factors for Purchasing Valves |

| Ball Valves Reveal: The Basic Concepts And Working Principle of The Whole Analysis |

| Maximizing Industrial Efficiency with Advanced Ceramic Ball Valves |

| Reason And Solutions of Corrosion in Industrial Valves |

| Do You Know The Pressure Test Methods of Industrial Valves? |